AXIOM Remote/Hardware v2

1 Abstract

For direct camera control an AXIOM Remote device is available. Following chapters describe the hardware modules and related components.

2 Prototypes

2.1 Prototype 2 (PCB v???)

Plans/considerations:

- Switch to two RP2040 microcontroller

- Flash storage (TODO: type and size?)

- Remove Second Knob (For menu navigation and the changing of parameters so far we found no use for it designing the UI).

- Light guide for "status" and "operation" indicators

- Light guide also as button illumination possible? maybe https://octopart.com/slp3-150-100-f-bivar-2289195?r=sp&s=KfHCVMw1QUq1RdKjDDNtJA - turns out this is a rather complex topic - skip button illumination for next revision?

- Remove left side rocker switches. So far we have not found any function for them. They are prone to being switched accidentally as they stand out from the device quite far. Having buttons/switches on the left side of the remote prevents it from being attached to the camera/rig on that side.

- Remove top side pushbuttons. So far we have not found a real application for them. In line with good user interface design / user experience these buttons need labels so the user clearly sees what is going to happen when he/she presses them. This is difficult as the label would not be visible from the front of the device.

- Reduce number of RGB LEDs to two (for status LEDs: State and Operation). So far we have not discovered any real world benefit to having RGB LEDs to illuminate pushbuttons. Changing the button illumination color to indicate something happening while pushing it makes little sense as while pushing it the users finger is covering the button making it impossible for the user to see it.

- Buttons will have built-in LEDs, We will see if we have enough lanes to control them individually.

- Add 4 more holes to PCB somewhere close to eachs PCBs corners so the enclosure back can be screwed together with the enclosure front. to save space some cutouts on the PCB would be handy for adding thread mount points to the enclosure in the middle of each side

- Shall we add additional PCB screw holes near the push buttons to add additional stability and prevent the PCB from being bent by force being applied to push buttons. Screw holes take away quite a big amount of routing space so the goal is rather to add support pillars without screws from the enclosure back where the pcb could be prone to bending due to buttons being pushed. replace slide switches for ON/OFF and LOCK with pushbuttons

- Decide on hardware vs software vs combination of the two: button de-bouncing

- Could be achieved through RP2040 hardware: https://gist.github.com/giripriyadarshan/4bf69b3a6cee5e8329f2d6e0f6ee85aa or https://github.com/TuriSc/RP2040-Button

3 Hardware dimensions

3.1 Enclosure

3.2 PCB

3.3 Display

4 Enclosure concept

4.1 October 2019

CAD design (work in progress): Link

5 Electronic components

5.1 General

- Microcontroller/s: two RP2040 Link

- Primary: general and UI logic, display control

- Secondary: button and knob handling

- Display: 2.8" TFT LCD, 320x240 Link

- LED drivers: STP08DP05, CAT4016HV6, PCA9957HNMP

- USB-C connector: Link

- Power supply: AXIOM Remote is currently powered externally via 5V DC supply (internal batteries might be considered for the future: 4x AA battery tray → cumbersome - lithium ion battery pack that is integrated into the remote and is automatically charged through 5V/camera would be preferred)

- Real-time clock (RTC): The AXIOM Remote has no requirement for internal RTC (plus button cell battery) - instead timecode is synced with/by a connected AXIOM Beta.

5.2 Connectivity

As we do not want to require a custom cable or a custom connector-cable assembly we try to stick with established standards that are able to transfer data (shielded) and power over the same cable.

To reduce the stress of leverage forces on connectors and the PCB we opted for the idea to use an panel mountable part or USB-C extension cable (panel mount extension cable) that is plugged into a USB-C connector on the PCB (SMT if possible).

5.3 Rotary encoders

The optimal number of detents seems to be between 20-30. 20 detents is pretty standard, 30 is not as widely used but still mostly available. We want a 14/15mm metal D-type shaft rotary encoder with push-button functionality.

CTS 290VAA5F201B2 is the current favourite, short 15mm shaft, it does not have a thread and nut for mechanical mounting but the click operation is close to silent, which no other candidate has from the samples evaluated so far: Link

5.4 Turning knobs

All aluminium, 30-35mm outer diameter, 15-16mm height, knurled outer surface:

Example: Link

5.5 Buttons

For the Prototype 2 hardware we want to test:

- Marquardt 3006 - 4N operating force - 1mm travel - Link

- Diptronics ML4L12WQR - 1.56N operating force - 0.25mm travel - Link

5.6 Extension ports

The extension port allows adding additional devices to the AXIOM Remote, this could be a wireless module, battery pack or additional dials and controls.

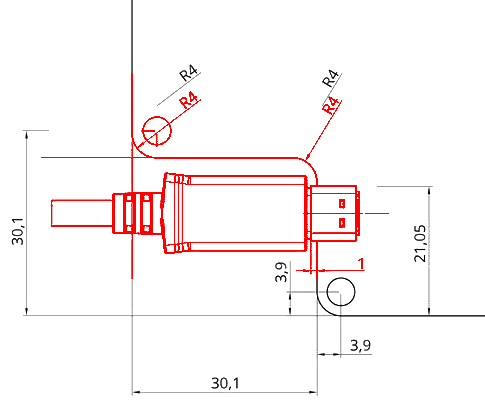

It utilizes a samtec IPT1-105-01-L-D-RA connector with two connectors of 2x5 pin banks each. The mating connector is called IPS1-105-01-L-D-RA.

The purpose of the connector is to provide power and data transfer to and from an extension module.

The Samtec connector is meant to be flush with the outside enclosure surface which means it extends 1.1mm beyond the PCB.

6 TODOs

- Add screw on lower left side: